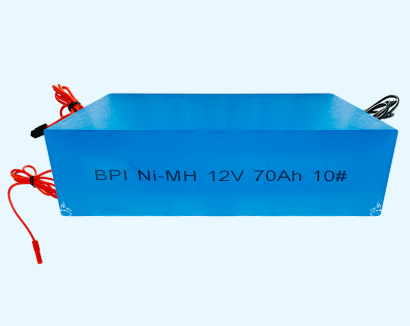

The most commonly used battery cells of beiteli battery pack are: polymer, steel shell lithium ion, cylindrical battery cells (lithium ion, nickel hydrogen)

The main naming method of battery pack is: according to the external dimensions of the battery: thickness, width and length.

Examples:For example, the cylindrical 18650 model refers to the electric core with a diameter of 18mm and a length of 65mm;

For example, the polymer (soft pack) model 903450 refers to the solid part of the cell with a thickness of 90mm, a width of 34mm and a length of 50mm.

3、 The production process is called pack process, mainly including connection process and wire tin welding process

1. Connection process

2. Wire soldering process

Connect the electric core and protective plate through wire tin welding, and then assemble the rubber shell. The equipment and tools used are mainly the tin welding table.

Well, that's all for today. If you have any questions about me, you can continue to ask me to answer them. Shenzhen beiteli is looking forward to your arrival!

BPI team gathered in Shiyan lake and successfully challenged the 4.5m high wall!

BPI team gathered in Shiyan lake and successfully challenged the 4.5m high wall!

BPI moves into outdoor energy storage

BPI moves into outdoor energy storage

BPI outdoor power supply to support Zhengzhou flood relief in action

BPI outdoor power supply to support Zhengzhou flood relief in action

Practical Guide: Rechargeable Batteries Information You Should Know

Practical Guide: Rechargeable Batteries Information You Should Know

nickel batteryoutdoor power storagepack batterylithium-polymer batterylead acid battery convert to lithium battery

precision electronicsoil pipelineAerospaceprecision electronicsaluminum industrynon-ferrous metalsvehicle manufacturingmold cleaningbridge steel structureother industries