With the popularity of smart phones and the maturity of Bluetooth wireless solutions, wearable products are booming. The most significant growth in the market in recent years is TWS true wireless Bluetooth headset, which has the trend to replace the traditional cable headset. The left and right headphones of TWS headset can work independently without wiring connection. Listening to music, talking and wearing body feeling are much better than traditional headphones, The small size and multi-function of TWS headset also have higher requirements for the internal chip. Rt9426 provides a complete electricity meter solution for TWS Bluetooth headset, so that TWS can have more excellent performance in electricity detection accuracy, energy consumption, chip packaging, battery life time, cost and users' experience of battery power.

The miniaturization, portability and long-term use of TWS wireless Bluetooth headset will have the following technical requirements for the electricity meter:

A set of TWS headphones contains three batteries, one in the charging box and two in the left and right headphones. These batteries not only have different characteristics, but also have relatively small battery capacity. Only through more accurate voltage and current detection and accurate power calculation of the electricity meter can we provide users with correct power information, inform users of the remaining service time, and decide when to use and charge, At the same time, accurate power calculation can also completely release the energy of the battery and prolong the service time of the battery.

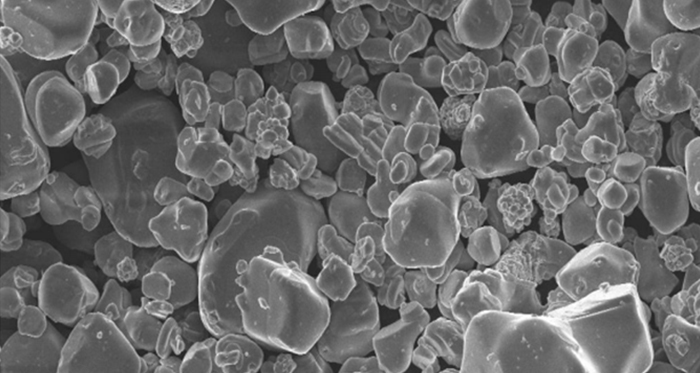

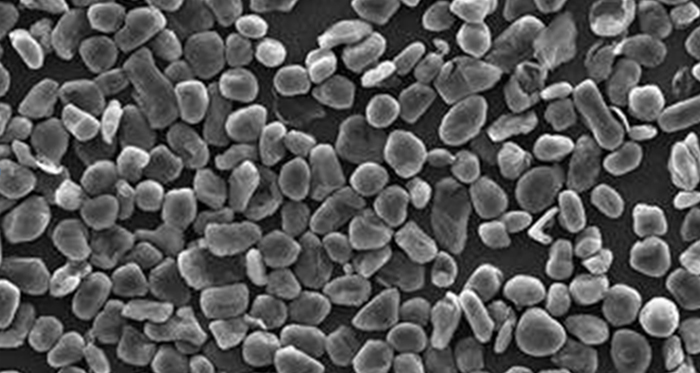

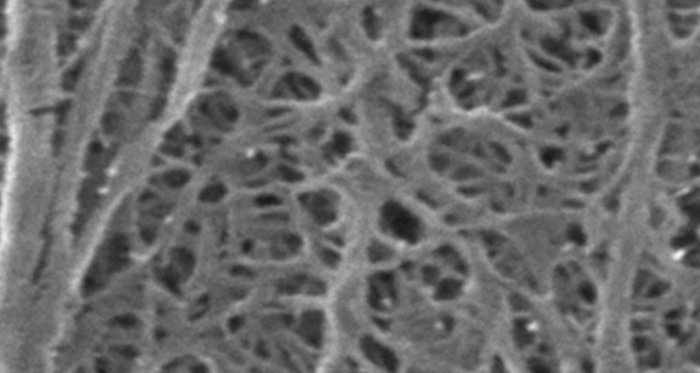

Product appearance drawings (sealed with aluminum-plastic film, various specifications of products can be customized for customers)

nickel batteryoutdoor power storagepack batterylithium-polymer batterylead acid battery convert to lithium battery

precision electronicsoil pipelineAerospaceprecision electronicsaluminum industrynon-ferrous metalsvehicle manufacturingmold cleaningbridge steel structureother industries